Bellow Expectations – An Interview with Eddy Warren

Eddy Warren

Eddy Warren

Eddy is currently the owner of Supaflex Agencies and has been in the bellows industry for over forty-six years. Eddy’s knowledge covers national and international rubber and metal bellow markets. He has worked on hundreds of projects, featured in many industry magazines and always tries to promote good British Made metallic bellows and High Grade EU Rubber Bellows.

Prior to working in this field, Eddy studied Mechanical Engineering at Anglia Ruskin University, Cambridge and also completed an apprenticeship. He then moved onto Jig and Tool/Special Purpose Machine design before moving onto the design of armoured vehicles, machine gun turrets and equipment for fighting vehicles. Eddy now has over fifty years experience in Building Services Engineering.

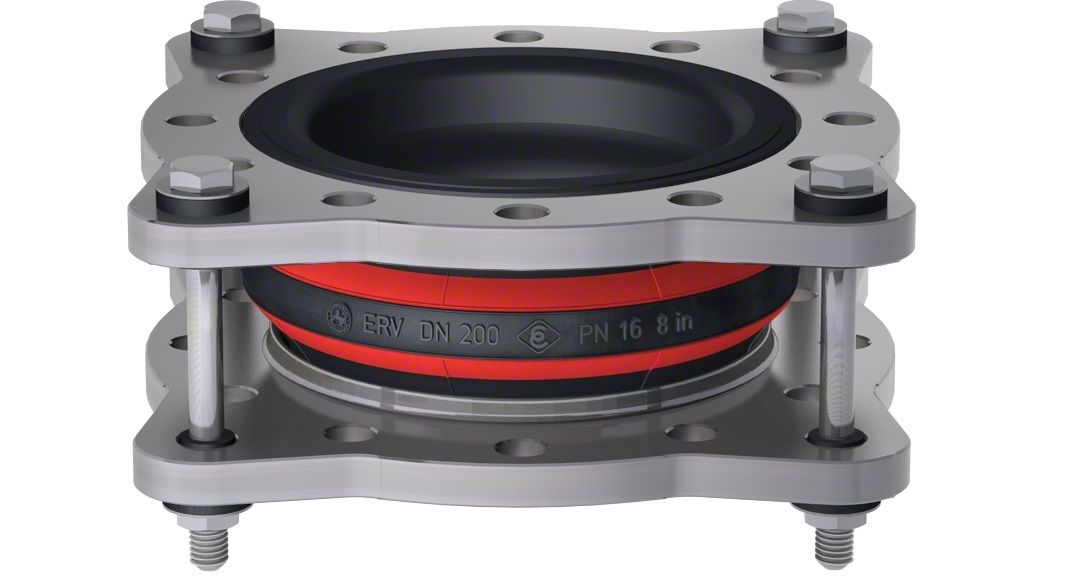

Following on from our interview with Dave Cooper, we talk to Eddy about the key role rubber bellows play in the running of plant equipment and metallic bellow use for expansion.

Q) Before we get started, for the readers who are unaware, what are bellows? Where and why are they used?

Rubber bellows are used mainly on pumps and plant to counteract vibration or stress on the equipment but can sometimes be used over structure movement joints in the building where pipes cross. All metallic bellows are mostly used for thermal expansion in the form of axial, articulated and hinged/angular.

Q) After being in the industry for forty-six years, how has it changed since you first started?

Many changes have occurred with the disappearance as we moved into the millenium of both Engineering Appliances Ltd and the Tube Investments Group – Powerflex Bellows. Today, some, not all, of the technical advice given is poor in comparison. A few companies sell metallic units where they are totally unnecessary which I find quite annoying for the reputations of those who give good application engineering advice.

Q) When installing bellows, what needs to be considered?

With metallic bellows, schemes produced for both M&E Consultants or Contractors always evaluate the pipe configuration relating to the supports. DO NOT add in a bellow if this can be achieved. Sometimes a very slight alteration on the configuration can eliminate the need to add one.

Q) What have been some of the worst bellow installations you have seen?

.jpg)

I have seen many failed rubber bellows imported in to the UK from the Far East – Chinese made in particular, with poor and dubious materials, especially the body reinforcing.

I have seen many failed rubber bellows imported in to the UK from the Far East – Chinese made in particular, with poor and dubious materials, especially the body reinforcing.

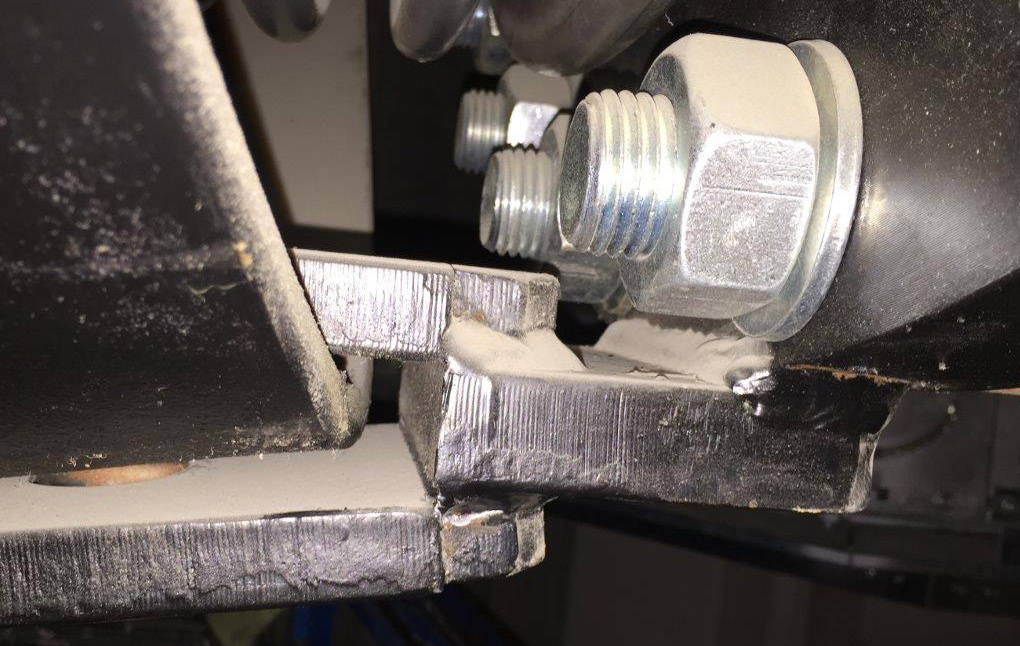

With metallic bellows installation the worst situation can be anchor failures and what contractors think constitutes a guide. Two guides should be each side of an axial expansion bellow 4 pipe diameters away then a further 14. Approximately 15% of the anchor thrust is on the first guide as a side thrust.

For one of the worst metallic bellows failures, I was sent pictures by a third party of failed Gimbal Bellows that had been installed, buckling on test. Me and several others were of the opinion it was not even necessary to have installed them in the first place and certainly they should have only been hinged/angular units.

The disaster at Flixborough in 1974 was the worst, but not the fault of the bellows manufacturer.

Q) Are there any standards or publications you would recommend reading before purchasing or installing bellows? Is there a BS En Standard?

No, but following some very dangerous incidents with Low Grade rubber bellows failure, there is ongoing encouragement to see a BS EN Standard for them, to match the German DIN 4809 standard. One of these incidents came very close indeed to causing a fatality.

With metallic bellows, the first BS specification appeared in 1981 – BS6129-1 after the ‘Flixborough Disaster’ in 1974, when the Nypro Cyclohexane Plant in North Lincolnshire was destroyed completely, killing 28 and injuring 36 out of just 72 on site on a Saturday. A mistake on site caused the unnoticed rupture of a (20”) 500 mm Stainless Steel Bellow. Metallic Bellows Standards used Worldwide are controlled from the HQ in the USA of EJMA – The Expansion Joint Manufacturers Association. This is now at version 10.

Q) As we come closer to the Brexit deadline, will this have an effect on the bellow industry? If so, in what way?

Post Brexit January 2021 could see both supply difficulties and price increases for some metallic bellows imported from the EU. Fortunately, there are still many making these in the UK. High Grade Rubber bellows from the EU could similarly be affected.

Q) There are no manufacturers of standard rubber bellows in the UK, are there any upcoming technological advancements that will improve the use of bellows? Where do you see the industry heading?

There is always R&D work with new ideas, particularly with Rubber Bellows. Elaflex/Continental in Germany originally introduced steel mesh body reinforcing in 1975-6 followed by (Kevlar) Aramid Fibre in the 80’s onwards then Polyester Ether Ketone (PEEK) in recent years.

Q) What could the industry do to improve the uptake on high-quality bellows and improve the overall minimum standard currently available?

Unquestionably, the BS EN Standard for Rubber Bellows needs to be brought in, even with UK Testing matching the work by TUV SUD in Germany for DIN Standards – resulting in DIN 4809. Followed by all M&E Consultants using it.

Q) Finally, what advice would you give someone looking to purchase bellows for their equipment?

With regards to Rubber bellows be very wary of where they are produced. Units produced in the EU are covered by stringent QA and body reinforcing standards. If the DIN 4809 Spec. is always used by M&E Consultants, until a BS EN Spec. could be brought in, it will ensure a high grade unit is always installed.

For metallic bellows application engineering make sure you bring in someone who can give sound engineering advice – not someone who will try and make a sale of an unnecessary item.