RHI Meter Calibration Briefing

In November 2011 the non-domestic Renewable Heat Incentive (RHI) was launched in the UK, closing to new applicants in March 2021. The domestic RHI was introduced in April 2014 and closed to new applicants in March 2022.

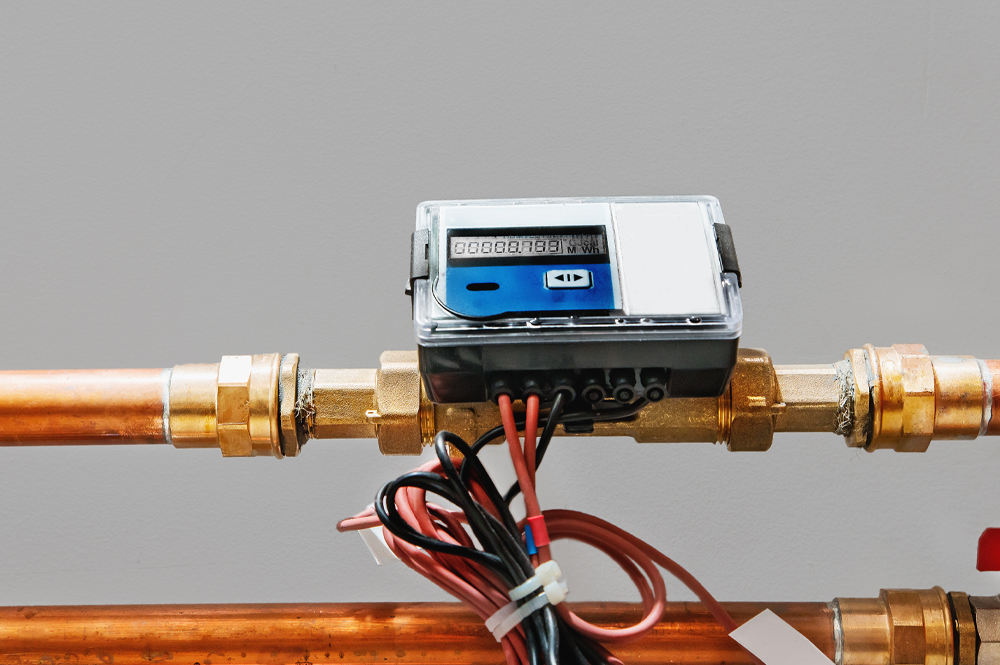

As part of the on-going obligations is the requirement to have meters “re-calibrated at least every 10 years, or in line with manufacturer’s instructions where available, whichever is the sooner”.

This means we are approaching a point whereby a very large number of heat meters will require recalibration or replacement (estimated in some cases as up to 100,000 meters).

According to the guidance1 to comply specifically with the meter re-calibration requirement, participants can choose to either re-calibrate or replace their meter and calibration of meters and associated components should be carried out by the manufacturer or by organisations with relevant accreditation.

An in-situ basic meter test would not satisfy this requirement as the regulations require the calibration to meet the standards set out in the guidance. Typically, it is expected that meters will be sent away for re-calibration by the manufacturer or an independent testing laboratory.

It is worth noting some of the issues with both these available options:

The majority of manufacturers do not recalibrate the heat meters or if they do, the cost is more than a new meter, so they prefer to sell a new meter.

The cost of sending off the heat meter and associated ancillaries to a laboratory for recalibration has several issues as well:

- Whilst the meter is removed, the system has to be drained down or isolated and the plant normally switched off.

- The cost for recalibration is circa. £1,800, far more expensive than a new meter and can take up to 6 weeks in some cases.

- The meter then has to be reinstalled, so the system has to be drained down/isolated again and the plant is switched off again.

- During the period that the meter is away for calibration, the heat is estimated based on the fuel usage.

Subsequently, operators are replacing perfectly serviceable meters with new and throwing away the old meters which is a considerable waste and in some cases hazardous due to some of the meters having batteries installed.

The biggest factors for inaccuracy of heat meters is air and dirt and Installation is one of the largest sources of uncertainty when transferring calibrations from the laboratory to the field2. So by removing the meter for either replacement or off-site calibration you are more likely to introduce errors in the measurement of heat.

It is also worth noting that under the CHPQA guidance3 “Meters without any in-pipe components including Ultra-sonic, Mag-flow and Coriolis meters…..on-site calibration using independent metering that is traceable to a calibration standard is acceptable”.

And according to DECC “It is recommended that wherever possible, in situ calibration be carried out for DECC research projects4.”

Finally, there is also the issue of will both Ofgem and the recalibration laboratories have the resources to deal with such a large influx of meters requiring recertification.

1. NDRHI Guidance Volume 2: Ongoing Obligations and Payments.

2. BEIS Heat Meter Accuracy Testing 2016.

3. CHPQA Guidance Note 13.

4. BEIS Heat Meter Accuracy Testing 2016.