2G Energy – Hydrogen CHP – CIBSE Certification – Webinar

On Tuesday 20th April, Martin Kenzie of 2G Energy leading a webinar on the UK’s first hydrogen CHP.

This webinar included:

- A look at the work 2G Energy have done over 8 years running CHPs with 100% hydrogen.

- The technical changes made to the engine design to enable hydrogen running

- Projects that they have delivered, the sources of the hydrogen and the environmental benefits of fuel switching.

Please see the video of the webinar and full transcription below:

Video Transcription

Andrew Geens:

Hello everyone, good afternoon.

Welcome to the April webinar for CIBSE Certification. This is Andrew Geens doing the introduction as normal.

A little bit of housekeeping, just to remind everyone, if it’s the first one you’ve been to we will record this and make it available through the news page on our website tomorrow and we also have a copy of the slides if you like to look through them at your leisure after the event so, that’s the main housekeeping items.

If I could ask you to use the question function if you have any questions for the speaker. We’ll deal with questions at the end but type them in as they occur to you using the questions function

Just a bit of a heads up, for next month we’re hoping to have something for EPC Assessors next month.

Okay. So we’re lucky today to have Martin Kenzie with us. Martin is the UK sales manager for 2G and he’s going to talk to us about using hydrogen as a fuel for CHP. So, I’ll hand over to Martin with no further ado and let’s hear what he’s got to say.

Martin Kenzie from 2G Energy

Martin Kenzie: Good afternoon everybody.

So this is our presentation that we run on the CHP technology that we’ve developed specifically around 100% hydrogen gas that we’ve been running as a fuel for about nine years now. So if you have any questions, once again you can just ask them and I’ll answer as best as I can.

Key Data

So, we’re a company a lot of people have never even heard of. We’re a German company based in the northern part of Germany. We’re actually close to the Dutch border so obviously our headquarters and manufacturing centre is in Heek, in Germany.

We actually design and build engines ourselves for the CHP industry with the third largest engine manufacturing CHP producer in the whole of Europe. We’re generally producing engines from 50 kilowatts, our own engines, up to 1 megawatt on natural gas and hydrogen and then obviously we also have packaging developed agreements when we need to obviously use larger power engines itself.

With 650 employees, but out of that 42 members of us are actually part of the research and development team, so an awful lot of the timing and efforts of the company is about designing and developing engines.

So we have 6,500 – 7,000 of these engines running in basically every corner of the world and we’ve got nine international subsidiaries, so we’re pretty much all over the world.

It’s just that a lot of people might never have even heard of us or actually know what we do for a living.

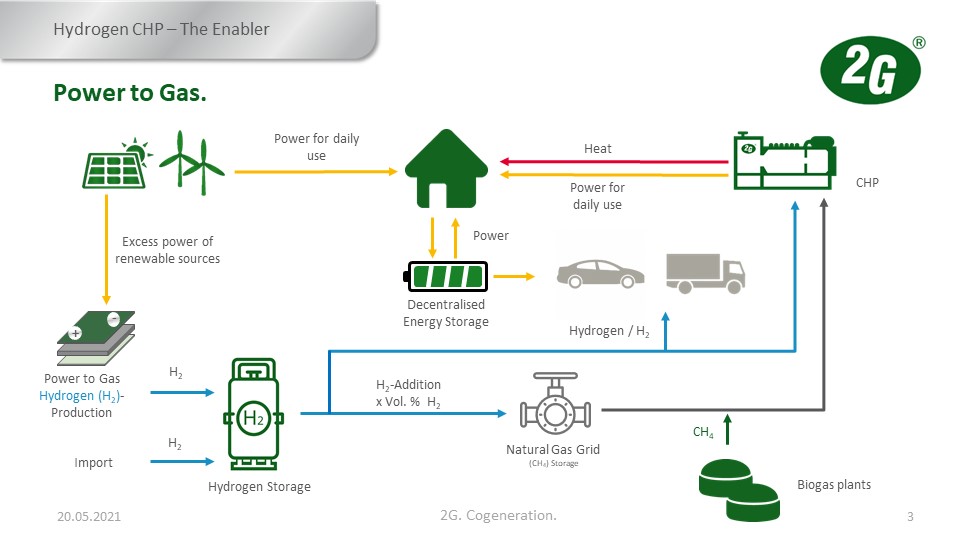

Power to Gas

So the power to gas sector is quite developing now in the last couple of years.

Originally, back in 2006/2007, the German government were thinking about what scenarios they could develop, either backing the battery economy or trying to back the hydrogen economy and at that point they decided they didn’t really like where the metal was coming from and obviously all the batteries and everything else.

The German government decided wholeheartedly they were going to back the hydrogen economy.

So an awful lot of work was put in for the development of how to produce hydrogen from electrolysis. There was an awful lot of excess wind energy in Germany and specifically throughout the whole Europe and the UK. So at night an awful lot of that wind energy was being curtailed with the wind turbines being turned out of the wind. Some of it was going into battery storage, there was a lot of it then being obviously being converted through electrolysis, splitting of water into hydrogen and oxygen, and obviously the hydrogen was being stored for, obviously, for use later on.

There was a lot of development work about the injection of hydrogen back onto the German gas grid initially. As well there was some work done about the methyl methanolization of hydrogen obviously putting the carbon back into it to make an official artificial form of methane and to run in the engines. But at that point in time it just decided this rather than obviously using metonization it was just better to actually just use the hydrogen directly into an engine.

So we started developing the hydrogen engines. Initially it wasn’t really that much of a great step forward. In a certain way, we’d already developed a lot of biomethane and syngas engines and syngas had 40% of hydrogen in it so we’d already developed the technology for running obviously high percentages of hydrogen into engines. And for us, as I said biogas, syngas, hydrogen they’re all just gases so it’s just a case of how we set the engine up and obviously how we play around with that engine.

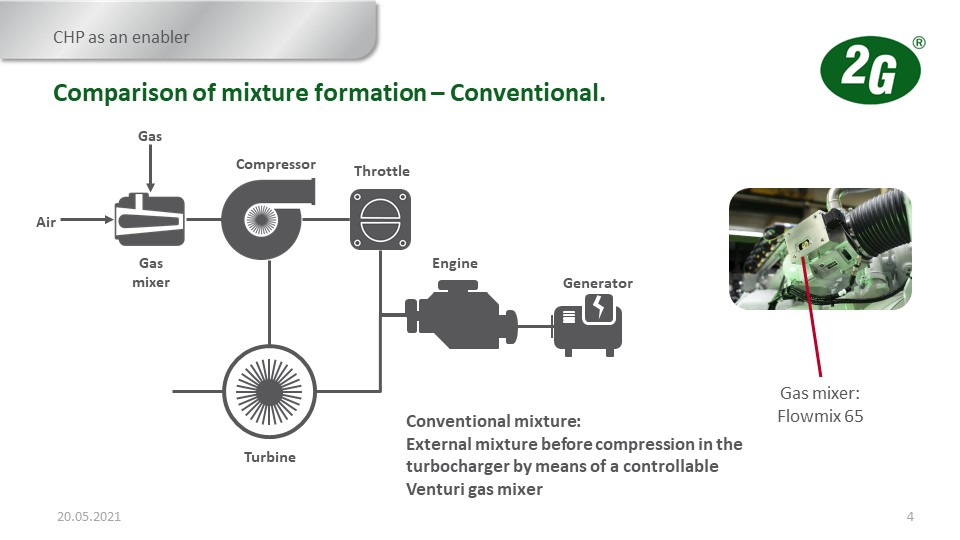

Comparison of mixture formation – Conventional

So, how we do it. So normally in a conventional engine, conventional reciprocating engine, the gas air fuel mixer goes through a supercharger before it obviously goes into the engine and specifically that’s how obviously you get the power outputs of high efficiency engines.

When we’re running hydrogen, especially above 40%, below 40% there’s no problem at all still running it through the turbocharger and injecting it in the standard way just obviously to put a gas mixer in the hydrogen blend with a natural gas in the same conventional way. What we found is that when we start moving above 40% of hydrogen blends, because of the combustible nature of hydrogen, because obviously it’s quite a low combustion point, you run the risk you can blow up the turbocharger if you start moving at higher than 40% blends going through a turbocharger.

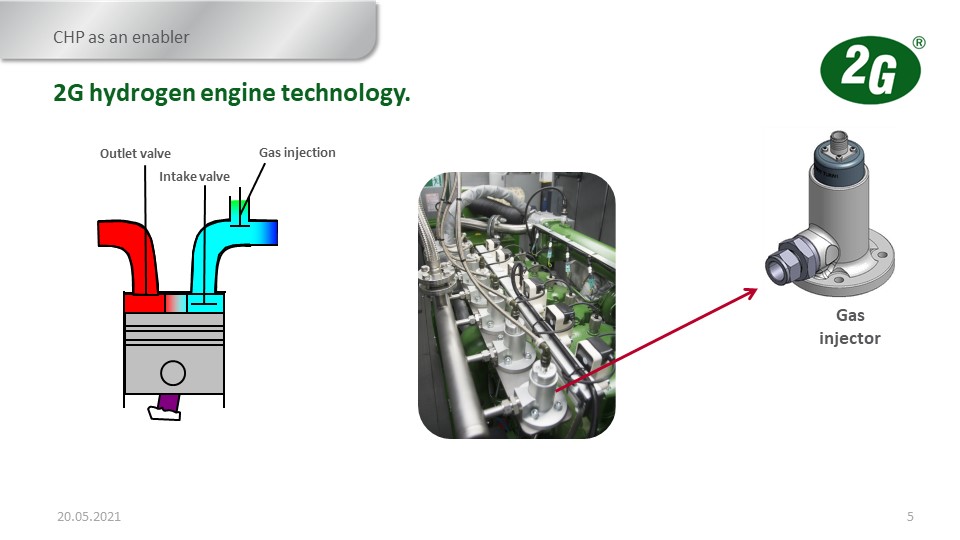

2G hydrogen engine technology

So all we actually do is we bypass this turbocharger to run with hydrogen of 100% hydrogen of 40% and above. So all this means is we just bypass the turbocharger. We put direct hydrogen injection or hydrogen injection directly above the cylinder heads so the air mixture still goes through the turbocharger and then obviously, just before it goes into the cylinder head, we mix obviously the hydrogen at that point into the engine. So this is what we do with all the engine technologies when we’re running hydrogen above 40% blends so below 40% there’s no problem at all running through the conventional mixer. Above 40% percent we bypass the turbocharger and we also do the hydrogen injection directly into the cylinder head. It’s not really that complicated about how you obviously convert an engine into running 100% hydrogen from a natural gas base.

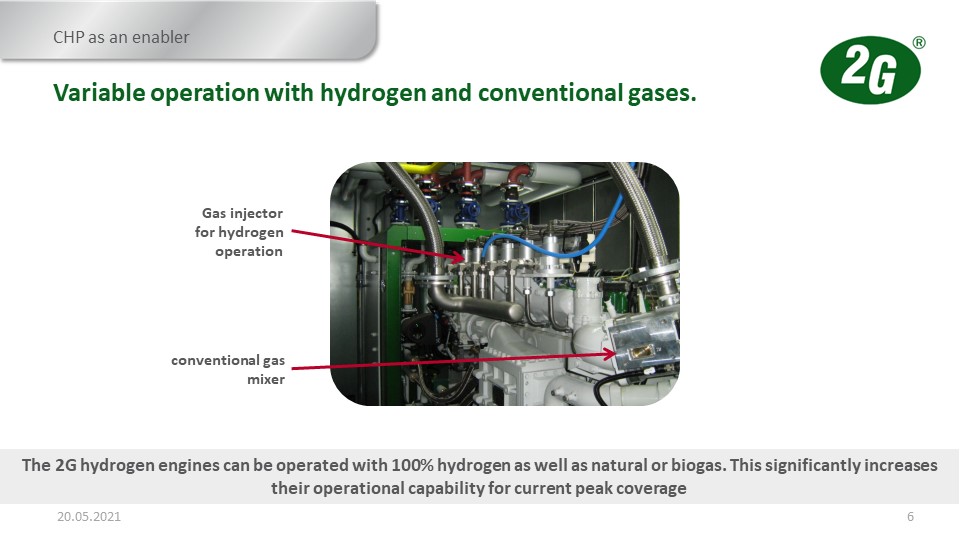

Variable operation with hydrogen and conventional gases

So once again, because we did an awful lot of this work with the development of various blends of hydrogen, we still have conventional gas mixers on the engine as well.

So it’s one of those cases where you can run 100% hydrogen into the engines if you’ve got it or if you’ve still got the requirements to run the engines and you obviously haven’t got the hydrogen available, you can then run natural gas or biogas or anything else through the engine in the same way.

It’s the same engine, it just runs a different way depending on what gas mixes and everything else you’ve got is. This gives great capabilities in some of the applications that we’ve run. We have hydrogen being generated at night so while we can run on pure hydrogen, we run pure hydrogen but if the hydrogen’s been depleted and the leisure centre still needs heat for their swimming pools etc. we can just put natural gas back into the engine and once again we have the technology.

This all happens completely automatically. So the switching in between different gases and everything else it’s not like you’ve got to be going there with a screwdriver to make the adjustments and everything else, it just all happens seamlessly. It just gives you a greater flexibility on the engines you can actually run with either types of engine or types of gases. 100% hydrogen or blends of hydrogen or back down to the 100% natural gas, bio gases or syn gases etc.

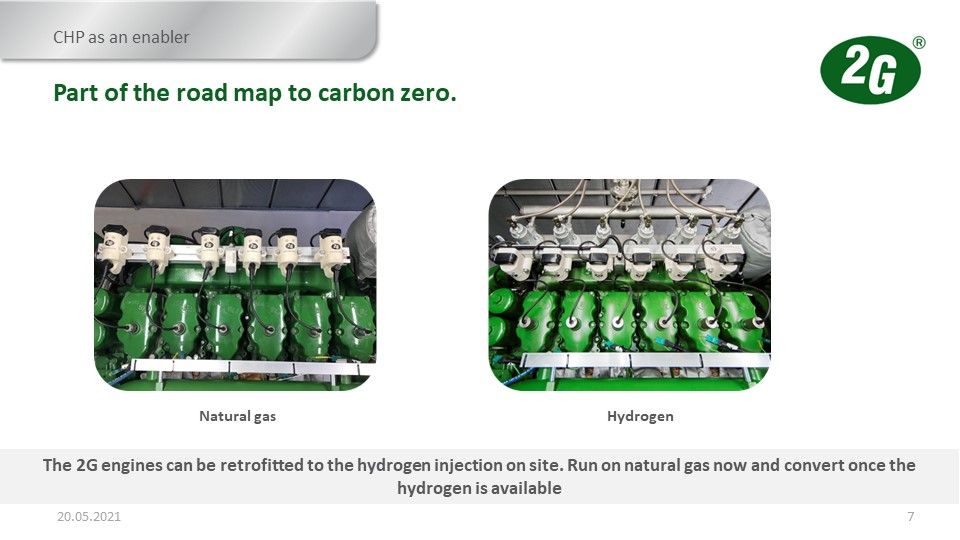

Part of the road map to carbon zero

So, once again, because this isn’t a new design engine, this is our existing natural gas engines just made to run with hydrogen, we can make the adaptation to obviously run on hydrogen anytime people want this.

As I said, the normal engines that we sell will run with 40% hydrogen without doing anything to it. So we don’t have to bypass the turbocharger, but if people say ‘okay we are now at a point where we want to run the engine, we want to run it on 40%, 50%, 60%, 100% hydrogen’, we can come back to site at any time and just fit the hydrogen injection system above the cylinder heads at any point in time.

So it’s not like you’re having to buy an engine now that will only run on natural gas or an engine that will only run on hydrogen. It’s exactly the same engine, just with a bit more technology put on top of it. So it’s not like you can buy something this is going to end up being a stranded asset. If hydrogen comes along and your natural gas engine can’t run with this. So a lot of the applications it’s you can buy the engine now and obviously run it on natural gas and as soon as hydrogen comes along, up to 40% you don’t have to worry about it, it’ll do anything, and as soon as you go over 40% hydrogen, put the injection system on it and then you can run on 100% hydrogen with exactly the same engine block without changing the infrastructure or anything else.

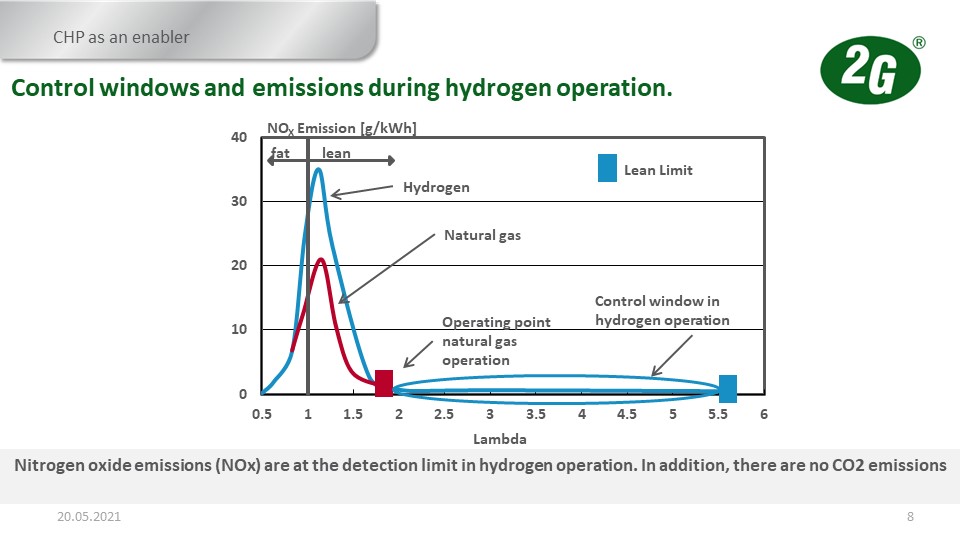

Control windows and emissions during hydrogen operation

So one of the big advantages with hydrogen is because it’s quite combustible which is the reason why we play past the turbocharger. It means we can play around the lambda number.

So the lambda is the ratio between the air fuel mixture going into the engine. So obviously a lot of conventional gases, natural gas, biogas, everything else, there’s a certain limit that you can put or air going into it before you can still combust and effectively get the gas to detonate inside the cylinders.

With hydrogen, because it’s quite combustible, we can obviously operate at higher lambda values and one of the big advantages of this is, the higher the lambda value, the more oxygen you’re putting through the engine so to get it detonating it lowers down the nitrous oxide emissions from the engine.

So it’s very easy for us to play around within this operational window to achieve whatever NOx limits are susceptible or required for the engine going out. I mean, when we did the original first engines that we put in as trial basis, we were running the engines at 500 NOx because obviously that was quite acceptable at the time, you know, based on the fact that the technology or the the emissions was based on the biogas world but we’ve got the engines now running down to 95 milligram NOx.

Exactly the same engine, slight little change on the powered outputs of the engine but it’s because a lot of the applications now, people are wanting these engines to go inside city centers, especially obviously running with hydrogen because of corporate headquarters etc. So it’s easy, once again whatever is required for the application we can play around. Just with obviously the engine tuning and the lambda value to make it achievable.

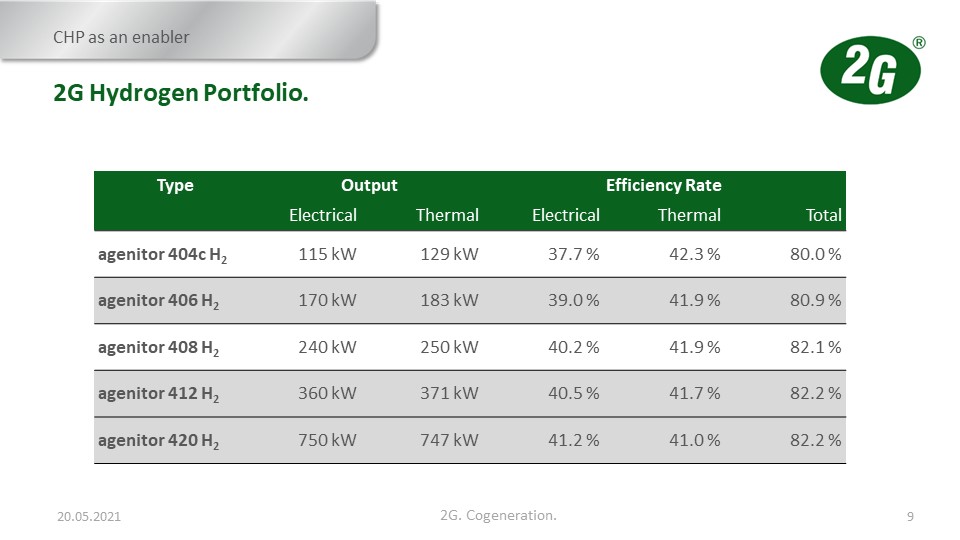

2G Hydrogen Portfolio

So once again, this isn’t just a single engine that we’ve got out. It’s not a trial test engine or anything else. We have our entire range of engines from our agenitor range of engines. So everything from our four cylinder all the way up to our 20 cylinder.

These are natural gas derivative engines but obviously we can have them running on 100% hydrogen, we do have them running. So, once again, it’s not a case because we’ve designed something and we’ve got one engine and we’re trying to make it fit every single application.

Anything from 115 kilowatts all the way up 750 kilowatts, these are pure hydrogen outputs. So once again it fits the applications having our range of engines but even our smaller, or our different, range of engines we can make them run 100% hydrogen as well.

Effectively any engines that we manufacture we can make run 100% hydrogen with exactly the same bypass technology in the hydrogen injection systems. So once again it’s a case that the engines are available to fit all the different applications and different engine sizes and everything else from our standard markets that we obviously deal with.

Examples

So once again, we’ve got these examples of engines everywhere. So we’ve been doing this since 2008 when we did the first engine which was in Berlin airport.

So that’s what you can see, obviously it’s a 306, so this is originally our three series of engines before we moved into our four series of engines now. So the very first engine we put in was a six cylinder engine of our three series but then since then obviously we developed the engines further into our fourth series and obviously increased efficiencies and now the entire range of our engines 4, 6 all the way to 20 cylinders are available either the standard natural gas or the standard natural gas with hydrogen injection system on them.

So we put these engines effectively all over the world, we’ve got demonstrated projects in Germany. A lot of these are in Germany. In fact the only one that isn’t in Germany, is the one we did in Dubai. We’ve got projects that we’ve done in Japan and obviously the ones we’ve done in the UK as well but I’ll cover all of the case studies a little bit now.

Case Study Berlin Airport

So this was the very first project we did. This was the project the German government did back in 2012 when they were trying to sort of determine whether the hydrogen economy would work.

So it was based on the fact that the wind farm was going to be running through the electrolyzer to produce hydrogen. It demonstrated hydrogen injection back onto the German gas grid. All of the vehicles on the Berlin airport are obviously running hydrogen fuel cells. It demonstrated low pressure low temperature storage of hydrogen and we put the engines on it to demonstrate we can run engines on 100% hydrogen.

So, once again, these are real problems, so if you pardon the covid lockdown, people can get on planes and go and visit these things. These are existing technologies. It’s not something we’ve come up with a whiteboard and said ‘yeah this is fine it might work’, these are actually things that have actually worked.

Reference

So, once again, this is the actual unit. It’s in Berlin airport. So you can actually see we’ve got the hydrogen injection system on it but we’ve still got the conventional gas mixer on the engine as well. So, once again, it’s still got that facility that we can run 100% hydrogen when the hydrogen’s available or if the airport still needs the heat etc. from the CHP at certain points in time we can still run the engine on 100% natural gas as well.

Hydrogen project in Dubai

So this was the project we did, I mean obviously last year if it wasn’t for Covid it was going to be the hydrogen expo, part of the world expo that was going to happen in Dubai.

So one of the things about the hydrogen expo is that it’s connected to the world’s largest PV farms, connected to electrolyze producing hydrogen. So the expo, all of the vehicles and the buses and everything else that we’re going to be running people around the expo were all hydrogen fuel cells.

We put on the engines to demonstrate running hydrogen through engines and producing the heating and cooling from the CHPs. So it’s the only project that we’ve done really that isn’t connected to an electrolyzer or that’s connected to a wind farm, obviously they didn’t need the wind farms over in Dubai where they’ve got the largest PV farms. So, once again, the hydrogen is produced effectively in exactly the same way through electrolysis, it was just a different electricity feed going into it being a PV rather than the wind farm.

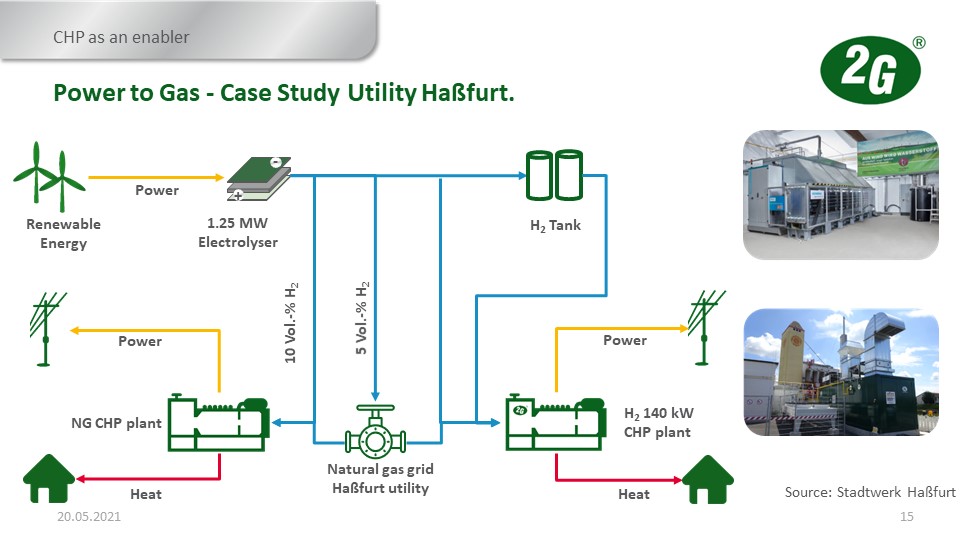

Power to Gas – Case Study Utility Haßfurt.€

So this was the project that we did over in Hassfurt down in Bavaria.

Power to Gas – Case Study Utility Haßfurt

This is the one that we’ve won actually a lot of the energy awards for. The CHP awards for last year and the year before. So Hassfurt, the municipality in Germany, years ago they had this ambition to become completely green. So they started building their own wind farms to obviously electrify the city or electrify the town.

It got to the stage where they actually ended up building a 200% of wind capability for the town more than you actually needed. So obviously a lot of the time, especially at night, there’s so much excess electricity available from this wind farm.

The 60%, 70% percent the wind turbines were turning out of the wind. So, once again, they decided that this didn’t seem to suit or sit well with them, especially because we were running natural gas CHPs there already.

So, they put on a Siemens electrolyzer, 1 ½ MW electrolyzer and during the night when they’ve got the downward and they were originally going to soften the downturn certain electricity, they run the excess electricity now into the electrolyzer and produce hydrogen.

Greenpeace by the hydrogen that’s injected onto the gas grid from this so Greenpeace they’re effectively calling it wind gas. So obviously it’s 75% blend going back onto the national grid or that they get German gas infrastructure they’re buying but it, once again, it’s a commodity that people will be using to offset their carbon footprints, effectively buying a hydrogen-injected gas onto the grid.

For us, once again, the hydrogen is stored in hydrogen storage tanks and we’ve got 140 kilowatt CHP. So, they obviously generate hydrogen which is stored during the night and then during the day when you need the electricity or the heat for the swimming pools and the schools they obviously run the hydrogen then back into the engine and we obviously generate 100 renewable energy off it. But, this is also one of the ones where the engines still got the capability of obviously running with natural gas.

So, once again, if we have the points where sometimes during the winter they still need heat coming off the CHP but all the hydrogen has been depleted or all the hydrogen’s been sold to the gas grid, we can actually run the engine on 100% natural gas no problem at all and it’ll happily switch backwards and forwards in between itself in between the two different gases.

District Energy Esslingen

This is one of the first district heating schemes that we did.

This is the district energy scheme in Esslingen, once again also in Germany. This was also really a sort of a demonstration project to demonstrate that you could actually run a district heating scheme with hydrogen.

So, once again, I said we’ve put in a small couple 100kilowatts CHP which is obviously supplying electricity but it’s also explained the thermal energy for the district network.

So, once again, it was just a demonstration project to prove that you could get a district heating energy system and effectively make it 100% green just by utilising hydrogen into the engine rather than a natural gas into the engine.

Going forward I think there’s going to be a lot more interest in these district energy schemes with the switch out of engines or switch out of the gas running the engines to actually make the district schemes, especially a lot of the ones we’ve got in the UK, go 100% green just by obviously changing the gas going into the engine.

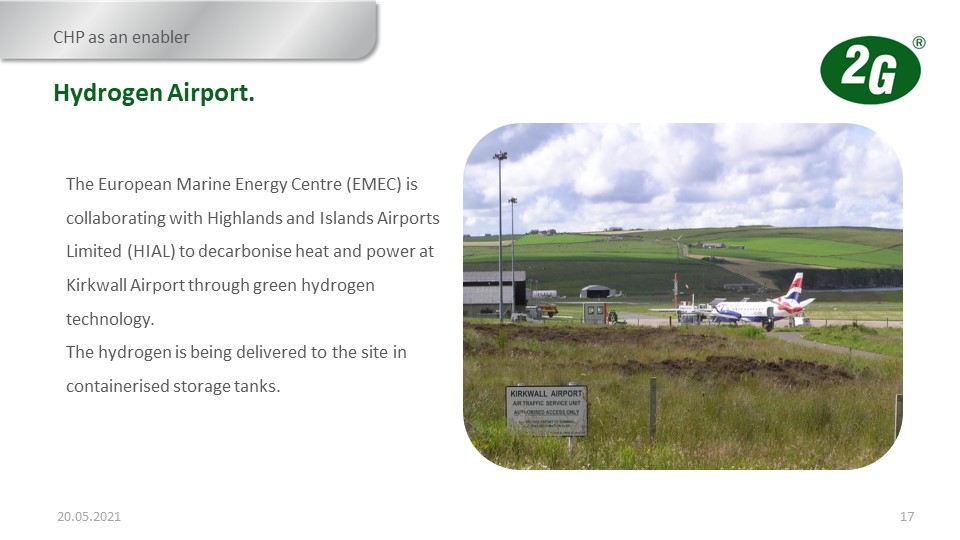

Hydrogen Airport

Orkney airport. This was the first project that we did in the UK. So, this is actually probably going onto the ground in the last couple of weeks. This is also a bit of a different project as well. This is the first one where the electrolysis equipment actually isn’t in the vicinity of the CHP.

So, marine energy center up in Orkney ,it’s where they do a lot of the tidal testing, is tidal turbines, so there’s an awful excess of electricity because the interconnected back in Scotland isn’t very good to be able to take all the electricity that’s being produced by the tidal power.

So all the electrolysis plants I think sit on Eday and the Eday produces obviously all the hydrogen from the excess electricity being produced from the tidal farms. It’s then being shipped into Orkney into containerized hydrogen storage vessels so obviously the hydrogen vessels are getting swapped in and out so the containerized units are being brought in and obviously one in one.

So this is the first project that we’ve done worldwide where the actual hydrogen is actually being shipped into the location. There’s an awful lot of interest as well, especially for temporary power or manufacturing building things like Reading and Glastonbury, the festivals where they obviously want to have some green energy being delivered.

With containerized hydrogen being delivered and obviously an engine that can run on it it is a good way you can actually generate green energy on site without all the the hassle of actually trying to generate the hydrogen on site in the same way.

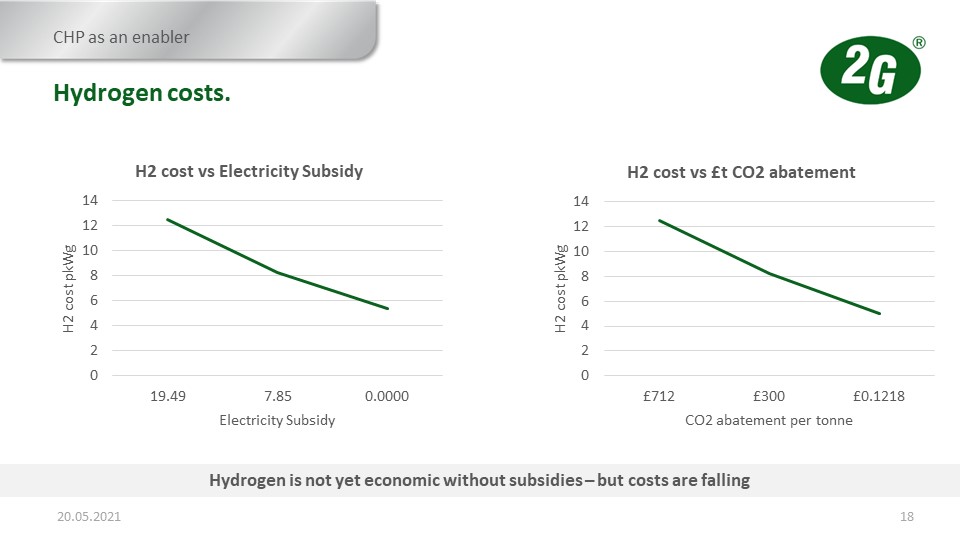

Hydrogen costs

So, it all sounds great, why doesn’t everybody just run hydrogen engines at the moment? The problem at the moment is none of this is economic and we’re not going to sort of blow smoke up people.

It doesn’t make sense economically at the moment, all the projects we’ve been doing have been done, they’re either funded from a different way. Ground funded by governments or municipalities none of it makes sense at the moment and the reason being is hydrogen, even from an electrolyzer but connected to a wind farm, is generally costing about 12-12.5p, where you can buy natural gas at 1.6p.

The economics of this is going to be changing when subsidies come into this. So it’s the same way this like wind energy from waste plants, PV, non-renewable technology when it’s in its infancy is not cost-effective so everything basically has to be grant funded or funded by a different way or backed up with subsidies to make it economic to start and kick-start the economy to get the gears spinning.

So, at the moment, we did an awful lot of analysis looking at which way it was going to be done and I think even BEIS at the moment I think they might do it through CfDs.

I think that’s the most common opinion that people have at the moment about the hydrogen economy or the hydrogen subsidies coming in.

The Dutch government are doing theirs based on the CO2 abatements that’s coming off the hydrogen produced from electrolysis plants. The Germans are sort of umming and ahhing about it but everyone, in a certain way, is just waiting to see what sort of funding or what sort of subsidy agreements is going to be put in place to make obviously hydrogen economic.

I think it’s the only way to start the economy, obviously you know to stop the economic development of hydrogen going forward, but everyone at the moment is just uncertain about obviously which way it’s going to be done but at some point it will come but it’s like we tell everybody that that’s why you can buy a hydrogen engine now but you won’t be able to run this because obviously unless you don’t see afford to obviously put the hydrogen into it or you can just buy a natural gas engine now, run it, you know at some point over that 15-20 years that it lives for adopt it then to obviously running on the hydrogen.

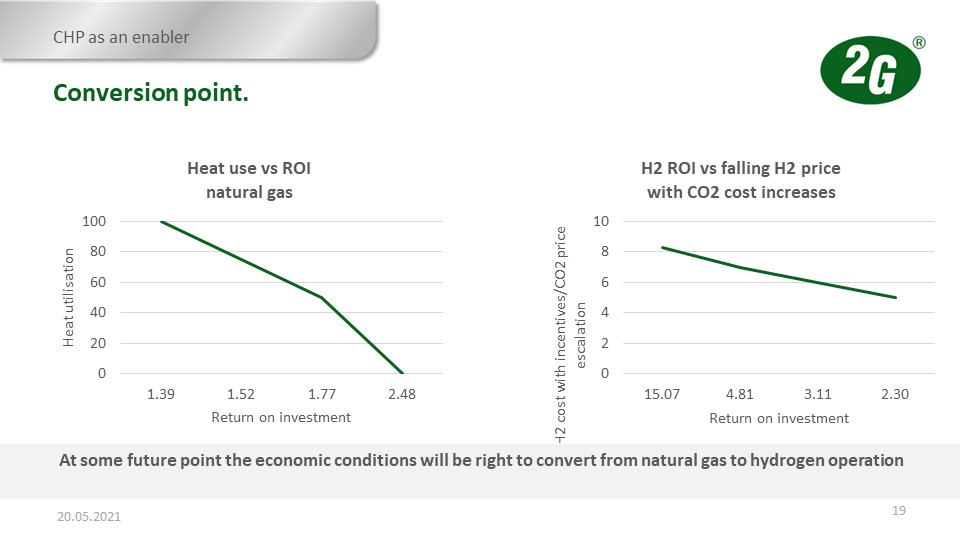

Conversion point

So, we do know at some point I said with hydrogen economy with subsidies and everything else starts kicking into place obviously with the hydrogen either being generated from blue or green hydrogen there’s going to be a conversion point when the return on investment running on natural gas and then the switch over to running on hydrogen it’s going to be economic. Then to obviously switch over and convert the engine to 100% hydrogen.

As the gas grid starts greening up anyway, I mean hydrogen injection is going to start happening, it’s just not legal at the moment until all the the safety protocols and everything gets changed, but as soon as it starts sort of decarbonising and more hydrogen comes into it and, as I said, up until 40% percent you can run the hydrogen, you can run the engines, without doing anything to it.

It’s just then obviously some of the key projects we work on people want to make sort of a method statement that we’re running 100% green energy, we’re running on 100% green hydrogen and then we can obviously make the engine or convert the engine to 100% hydrogen at any point in time. Or failing that people just buy the engine directly out of the factory already with the hydrogen injection system on it in the same way that’s what we did in the Orkney project, the engine was delivered on site 100% hydrogen ready from day one. It was really a case of watching this and seeing obviously what sort of points do you decide whether it’s an economic point or whether it’s sort of like an environmental point what you actually want to do with that engine and how you want to run it, but let’s say for most it’s quite easy and it’s just a case of watching it and playing around with this.

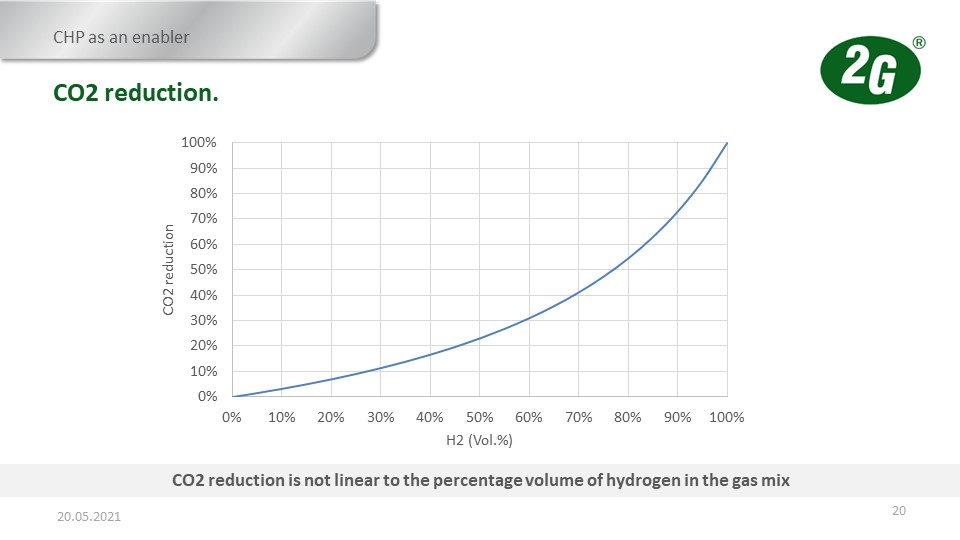

CO2 reduction

So this is one of the things that’s quite interesting as well because people think as the gas grid starts hydrogenating and you get up to this 20% threshold, everyone thinks it’s going to stay up for a couple of years, they think obviously you’re going to get 20% carbon reduction from putting 20% percent volume of hydrogen into the gas grid.

It doesn’t exactly work like that because obviously the calorific value of hydrogen is a lot less than natural gas. Putting 20% hydrogen into the natural gas grid only actually really gives you probably about 8% or 9% CO2 reduction just because of the energy intensity of the gases but once again it’s still one of those things, it’s still part of the the journey or the part of thinking about how you can get to carbon zero.

So as you amend the volume or the percentage of hydrogen blend and natural gas starts increasing obviously the carbon reduction starts increasing. I mean, ideally, you want to hit the 100% mark but whether it’s going to be 100% that’s going to be in year 1, 2, 7, 10, 15, once again it all depends on people’s appetite for what they actually want to do with that engine.

I said if they allow the natural progression of the hydrogen injection into the gas grid to start creeping up to the 20%, fine that’ll give them roughly about an 8% carbon reduction on their own engine or if they want to make the statements or ones that have the the renewable credentials for running 100% energy then you move obviously to 100% volume of hydrogen going into the engine but it’s not a linear massive scale, it’s one of the things that people need to understand about hydrogen injection because people think ‘oh well the gas grid will have 20% hydrogen in it, that’s 20% of our carbon target done’, in reality, it isn’t.

Conclusions

So, in reality, hydrogen engines are more than fuel cells. There’s an awful lot to talk about fuel cells but one of the big advantages that an engine has over a fuel cell, the fuel cell needs effectively 99.999% ‘the five nines’ pure hydrogen to run it.

We don’t, as I said, these are just gas engines whether it’s hydrogen or biocatalyst or syngas or anything else. So we don’t need 100% pure medical grade hydrogen into the engine but we can take gas impurities into it and the engine will run no problem at all.

As I said, it isn’t an issue for us. We can even use hydrogen as a byproduct obviously of industrial processes into the engines in the same way we did with syngas. One of the big advantages also about the engine as opposed to a fuel cell we can run partial loadings into an engine no problems at all, I mean reciprocated engines are designed to run anything from 35 to 100 load and anything in between, so we can modulate the engines up and down, day in day out, you can’t really do that with the fuel cell because it starts cracking down the cells. A fuel cell effectively really likes being switched on and left at 100% load all the time and, for us it’s just a gas, it’s nothing new for us, it’s nothing new technology or anything else and because it’s effectively the same core engine that we use in the same core controller and everything else nothing really has changed apart from the gas.

They still integrate into virtual power plants and do island modding and everything else and exactly the same way we did with standard engines because for us it is it’s standard engine with a bit of hydrogen injection system on it. That’s all that is and, once again, I said the ability to run mixed gas streams through the same engine, natural gas or biogas, syngas, any combination or any sort of blends in between it’s easy, it’s adaptable.

Whatever you’ve got actually we can run the engine on it. So that’s it really. I said it’s for us it’s nothing too groundbreaking, it’s not rocket science, it’s effectively just a gas engine that all we do is we just change the gas input into it and we just make it run. I said using an injection system and bypassing the turbocharger that’s effectively it.

Thank you very much for your attention!

So, if anybody’s got any questions?

Q&A

Andrew Geens: Okay, thank you Martin, that was very interesting.

We have got a few questions already but if anyone else has any questions please get them typed in.

The first question, Martin, came in before you got to the Orkney slide and the Orkney slide may have answered it partially, so maybe it’s more about scale. So the question is:

Q: Could you use this equipment for a portable generator setup or does the infrastructure to supply the fuel limit that as an application?

Martin Kenzie, Answer: Strangely, no because we’re having an awful lot of conversations at the moment about temporary power, I mean generally I mean a lot of the times 90% of the application the CHP is obviously integrated into a building. But we’re actually we’re having an awful lot of conversations at the moment about supplying the CHP containers that can be used in temporary power situations whether it’s building sites or whether it’s music venues and once again there’s a lot of work being done in some of the scandinavian countries about producing obviously containerized hydrogen deliveries.

So once again we can deliver an engine to size, whether we’re doing it or whether a temporary company are doing this, and then effectively you have two containers, you have the container with the engine inside this and you have a container obviously with the hydrogen storage in this and then once again it’s just connecting on to it in exactly the same way you could use a diesel generator except it’s a natural gas generator.

Depending on the applications, a lot of the science you wouldn’t even envisage running it as a CHP. We envisage just running, it’s a straightforward gas engine, a gas generator, we wouldn’t even put the heat recovery heat exchangers on it. So yes it’s very viable and there’s a lot of conversations we’re having about that specific thing specifically around building sites, obviously because people don’t want diesels generators if they’re building obviously low cost housing or low carbon housing and also things like music venues etc. So, yeah, it’s definitely happening and those conversations are happening already.

Andrew Geens: Okay that’s great thanks.

Q: To an extent, does that help request the technology ahead of piped hydrogen supply?

Martin Kenzie, Answer: Once again, I said that the applications that we’ve been looking at for this specifically are about so that they wouldn’t need temporary installations.

They wouldn’t need effectively piping up because obviously there’s no hydrogen infrastructure at the moment anyway so it would be a case of this and you end up with an engine being delivered and you have a hydrogen containerized storage solution being delivered and obviously that the container with obviously the hydrogen stored have all the gas in it to drive the engine. And then it’s just case of how large or how much density of hydrogen you need inside that container or that storage vessel. And how long do you want to run the generators for. But, yeah, be any sort of like piping up into a gas infrastructure or anything else it’s effectively like you have a diesel generator and you have a diesel fuel tank sat next to it. You would have a hydrogen engine and you would have a hydrogen fuel tank sat next to it, it’s exactly the same thing.

Andrew Geens: I wondered whether off-grid applications that use LPG were sort of close parallel to this as well?

Martin Kenzie: Absolutely. I mean we run an engine sometimes on LPG anyway and, once again, I said it’s all dependent obviously on the size of the engine and obviously the size of the storage vessel because obviously I mean if you wanted say a megawatt engine, you might be changing that container every two days to get it filled.

Once again, you then start thinking about whether you would actually use something like liquefied hydrogen and then obviously having an evaporator to convert it back to a gas to run into an engine. Once again, there’s an awful lot of conversations that are going on about that about what storage medium is needed depending on obviously the quantity of gas and the release rate that’s needed.

A lot of the times I said we’re specifically talking about gases but we also know in the larger applications we’re also talking to a lot of people who were thinking about producing liquefied hydrogen.

Andrew Geens: Yeah, okay. A couple of quick answer questions. Somebody’s asked:

Q: The units “pKwg” on the hydrogen cost graph on page 18, what is that unit?

Martin Kenzie, Answer: pence per kilowatt of gas.

Andrew Geens: Right, okay.

Martin Kenzie: Yeah, I mean, as I did these slides about probably three years ago now. So when we were starting to think about this and obviously started to think about obviously where the sort of the financials or the economics of this sat, so we’ve done some calculations based on obviously where it was at the moment and what we need to get a breakeven position.

That’s why it says 19.49 at the bottom. So effectively we didn’t know three years ago if BEIS was thinking about doing it on ROCs or something like that equivalent. So we knew generally we could get hydrogen for about 12.5p per kilowatt so we thought right if we’re trying to get to a breakeven point of 15 or 20 years we’re going to need ROCs subsidies about 19p, which once again that’s nearly triple or four times what ROCs payments normally are. And then we thought okay, but what different prices of hydrogen do we need to be to be that breakeven, what sort of subsidy is needed to hit that breakeven position and that’s why we got down to the stage where we needed about 5-5½ pence of hydrogen to be in a breakeven position of 15-20 years.

It’s still not an economic position but it’s that breakeven position where you might be then saving several thousand tons of carbon, even though it’s not an economic payback or it’s a net present value zero position so it was just a lot of different calculations we ran about where we think the price of hydrogen has to be before you don’t need any subsidies. And, I said, it isn’t even the case where you have to get the hydrogen down to like a 1½p/2p where natural gas is to make it work or to make it sort of breakeven. You just generally have to be around that 5p-5½ p without any subsidy at all to make it economic and we see that coming up as electrolyzers start getting bills and obviously the cost of those starts coming down and because obviously one of the big costs of generating hydrogen which is obviously part of the electrolyzer is actually the cost of electricity.

But, there’s some of the novel contracts now where people are looking at because if people have ROC contracts on their wind farms, they want those wind farms spinning especially at night. They don’t want then staying out of wind so some of those are able to offer effectively zero cost electricity contracts at night so then all of a sudden you’ve got zero cost electricity going into an electrolyzer producing hydrogen because the wind farm company was getting their subsidies by the ROC payments. So, once that changes the economics as well about how people are actually looking about the model of this about where the cost of hydrogen production is going to be.

Andrew Geens: Okay thanks, another quick one.

Q: Are you able to quote a rough figure. What is the cost per kilowatt hour for the additional injectors to convert to hydrogen?

Martin Kenzie: It’s about 15% of the engine for us to convert an engine to 100% hydrogen’s. Roughly 15%.

Andrew Geens: Yeah, okay. Getting quite a list of questions now so I’ll keep moving. Someone’s asking:

Q: Whether there’s a safety concern because hydrogen is colourless?

Martin Mckenzie Answer: Not really. Once again, I said, I mean millions of tons of hydrogen are being used all over the world already anyway in industry and everything else but no we haven’t really had any concerns about the colour of it or the lack of colour in it.

Andrew Geens: Yeah, perhaps in a boiler rather than an engine flame colour which is useful for a gas engineer might not be the same with hydrogen. Also someone’s heard about a trial for a hydrogen grid pipeline in the north of England.

Q: Is that something you’re aware of?

Martin Kenzie Answer: Well there’s lots of projects going on. I mean, there’s the h-100 in Leeds, there’s all the projects up in Dundee. I mean, Dundee’s fighting for itself, probably the first hydrogen city in the UK. There’s the Acorn project, they’ve got some. Grange Mouth. I mean that one project that’s a big electrolyze connected to the of the the Scots wind farms and if that comes online in three years time they reckon that could that can put 6% or 7% hydrogen into the entire gas grid just on one project but that’s why in places like Dundee and stuff they’re also looking at putting in 100% dedicated hydrogen pipelines and that they put up with calls for industry on who might want to connect to that pipeline.

I mean, in Germany, where our manufacturing site is in the next 12-18 months, we’ve got a 100% dedicated hydrogen pipeline going around the back of our factory.

Andrew Geens: Yeah, okay. I think you may have answered this but someone’s asked with a specific number so I’ll just put that number into the mix. It’s about viability at a smaller scale, less than 500 kilowatts?

Martin Kenzie Answer: Well, once again, the smaller engines we’ve got I mean the one in Orkney’s only 115 kilowatt engine. It’s like everything else, generally the scale of the economics gets better and better and better as it gets bigger and bigger and bigger, but once again at the moment electrolysis isn’t a certain isn’t that sort of issue, it’s the actualizer probably might cost more than the engine itself. But, once again the economics don’t work at all in any sort of scale so that’s why most of the projects we’ve done people are thinking “well, if it’s not going to work economically why go for a megawatt engine when that’s ten times more non-economic than 100 kilowatt engine”.

So, that’s where it is at the moment, that’s why a lot of these are effectively demonstrational trial projects to prove the infrastructure and everything else but obviously as the electrolyzer sort of like industry or the I mean everyone’s just waiting as effectively for BEIS to make the announcements on what the subsidies the hydrogen generation and then as soon as that happens, I mean most of the electrolyzer companies, I mean, they’re building like gigawatt factories to try to produce electrolyzers. They’re just waiting to see what’s happening because it’s like the thing at the moment you can produce the hydrogen at the moment but unless you’ve got a use for this what you’re going to do with it you can’t inject it into the gas grid at the moment in the same way you can biomethane but all of those safety legislations and everything else are all getting changed in the background so sometime later this year maybe next year you’ll be allowed to inject hydrogen into the gas grid. The same way you can biomethane and, once again that then kick-starts that economy. But it’s the wind, it’s the thing because we have too much wind. I mean, generally, throughout the whole of Europe about 30% of the wind farms have to turn out of the wind at night, so there’s so much wasted potential energy and you think well rather than waste it convert it to hydrogen, make hydrogen, that’s how most of the projects that we work on work as all the ones in Germany they’ve just produced hydrogen at night. They’ve got no other use of that electricity so rather than just having an idle wind farm not doing anything produce hydrogen.

Andrew Geens: Yeah,makes sense. Okay some more technical questions.

Q: With a naturally aspirated engine, can you run 100% hydrogen without modifications or changing the injection system?

Martin Kenzie Answer: Yes

Andew Geens: That’s a nice easy answer. It was only going to be yes or no.

Martin Kenzie Answer: Yeah, it’s only on our turbocharged engines where we get the problem. I mean all ranges of engines generally aren’t turbocharged anyway. We were concentrating on our generator range of engines to start out with because of that charge we’ve got a higher power output of them because, generally speaking, normally when you run 100% hydrogen you’re getting about anything from a about 20% d-rating of the engine because one of the issues with hydrogen it’s got no knock resistance. So, you can’t run the engines at the moment obviously with the same power output as you start getting knocking on the engine.

The R&D departments are working on that because at the moment we’re injecting hydrogen, probably about 4 bar, into the cylinder heads. We reckon if we move up to maybe 20 bar we can alleviate the knock issue on the hydrogen and then we’re effectively going to be running the engines the same power output on hydrogen as natural gas.

Andrew Geens: Yeah. So next question I think is related:

Q: When you switch over from natural gas to hydrogen, what effect does that have on the output from the engine?

Martin Kenzie Answer: Well, normally, yes. I think if we’ve got the engine set up to be running 100% hydrogen then we switch obviously to natural gas. I mean, it’s what we call a blending line. It’s something that develops for the biogas industry where sometimes if the biogas digesters didn’t have enough biogas they obviously still wanted the heat to run the anaerobic digesters. So, we always developed this technology to run natural gas into biogas and for the blending to keep the engines running . If we’ve set the engine up to run 100% hydrogen we wouldn’t go higher than the power output of the hydrogen. So, once again, if we’ve got the hook like our one megawatt engine , if we’ve got the hydrogen injection system on it and it’s configured to run at 750 kilowatts that we’ve run on hydrogen, they’ll be running on hydrogen. If we go on to natural gas we’ll still run it at 750 kilowatts, we don’t bother putting the power output out otherwise it means we have to change the compression ratios and everything else in the engine.

Andrew Geens: Yeah, I guess that question was driven by what you said earlier about the difference in calorific value.

Martin Kenzie: Yeah, no well, as I said it, even though we get a de-rated running hydrogen specifically because we don’t want to get the knocking issues on the engine, because the engine sort of like shake itself to death, once we’ve de-rated the engine once we know we want to run that derated value on natural gas we just have the ejection of the natural gas going up to that same value. We don’t obviously overpower the engine again.

Andrew Geens: Okay I’ve got a question about the Dubai project.

Q: What mix was considered and what was the life expectancy? What was the efficiency between natural gas and hydrogen?

Martin Kenzie Answer: The Dubai project doesn’t have anything to do with natural gas, we don’t even have a gas mixer on it. It’s a 100% hydrogen dedicated engine.

The reason being is because it was part of the hydrogen expo they wanted to demonstrate that you could produce. Obviously, the middle east wants to get into the hydrogen economy because to use hydrogen obviously all you need is wind, sun and water. Well, they’ve got an awful lot of sun, they’ve got an awful lot of deserts and they can get water so they can see that they want to move their economy from a basically chemical or petrol industry into a hydrogen economy. So, it was really a demonstration project that you could produce hydrogen using your sunshine and water so that that’s why the hydrogen expo was there to demonstrate you can use hydrogen engines.

You can use it in fuel cells, the buses etc. That’s all it was so it was just a demonstration project. I mean, obviously, they weren’t policing too much about the economics office because they’re not exactly short of money but I said it was never intended to run anything but 100% hydrogen into that engine. The efficiencies are basically the same whether you’re running hydrogen or whether you’re in natural gas.

Andrew Geens: Yeah, okay.

Q: Another question about the portable situation. I think someone’s asking about the cost-benefit analysis on using this to fuel emergency standby generators rather than 35 second gas oil. Would there be a size at which that would become an option?

Martin Kenzie Answer: Well, once again, but this is something that’s at the NHS and a lot are looking at this at the moment.

Now, the the NHS is quite funny actually because up until 20 years ago, I’ve done this an awful long time, 20 years ago like CHPs were the greatest thing ever for doing the NHS carbon targets and so that’s why we saw massive CHPs into all the NHS and then obviously the last couple of years people have been arguing saying ‘oh yes you can’t use CHPs anymore because obviously the carbon position’ and so the environmental people were the biggest prohibitors for CHPs and hospitals until they worked out that they’ve got this 20-40% carbon zero target and they had no idea how to do it.

So we met an awful lot of them, we said well it’s dead simple all you’ve got to do is just run the engines to100% hydrogen, that’s 80-90% percent of your target done. It’s at the same point they went, can we get rid of our diesel generators and have the hydrogen storage and have basically two engines, one that’s doing the primary power at hospital and one is the standby set. So effectively yes.

Andrew Geens: Yeah, okay. Another one that’s going to be a yes no.

Q: Does hydrogen accelerate valve wear?

Martin Kenzie Answer: Well, yeah, not really. Everything that we put onto the engine because when we do what we need we change this and obviously cylinder liners and everything else. Everything that goes on to the engine for the hydrogen running is obviously hydrogen, all the metal and everything else is all it’s all specified for running on hydrogen.

Andrew Geens: Yeah, okay.

Well we’ve more or less exhausted the questions.

That was a really interesting presentation and a really interesting Q&A session. Very timely actually the last question I’ve had is someone who, I think, missed the start because they’re asking if we provide a copy of the presentation.

So just to remind everyone the presentation has been recorded and the copy of the recording and a copy of the slides will be available on our website sometime tomorrow on the new section of the CIBSE certification website.

So, thanks again Martin for providing that. That was very informative and it’s very much a watch this space situation I think.

Martin Kenzie: Yeah, no problem at all, thank you very much.

Andrew Geens: See some of you at the next one next month and I’ll say goodbye for now and close the session.